Quality Control

Seeds produced around the world are collected at Sakata Seed Corporation for testing, treatment, and processing to ensure that seed quality meets or exceeds applicable criteria. The quality of seeds cannot be determined by their appearance alone. Sakata Seed Corporation has established a system to commercialize high-quality seeds that have passed testing in compliance with international standards and the strict criteria defined by Sakata Seed Corporation. This system ensures that our seeds can be used with peace of mind.

Basic Policy of Quality Control

Sakata Seed Corporation implements strict and objective quality control procedures in order to deliver high-quality seeds to our customers. The basic policy of our quality control is “reliable quality testing using reliable procedures” and “quality evaluation from a customer perspective.” Each staff member is engaged in work with a strong sense of responsibility and high aspirations. To realize quick and accurate testing, we utilize the merits of being a global corporation to expand our testing system globally to North America, Europe, the Middle East, Africa, Asia, and South America. We are engaging in global collaboration with the aim of thorough quality control and improvement of testing technology.

Plant pathology research

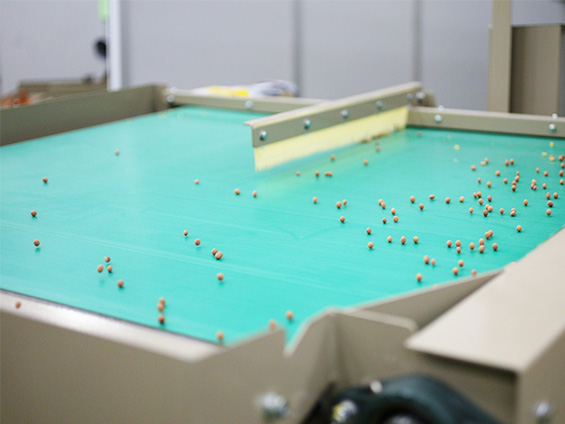

Sorting Quality Seeds from the Harvest

Selection based on the weight and shape of seeds

Physical purity test being conducted visually

Seeds delivered to Sakata Seed Corporation at locations around the world are stored in warehouses with appropriate temperature and humidity set for each product. The desired seeds which have just been collected from the field are also mixed with foreign substances. Impurities including stones, sand and soil; branches, flowers, calyxes, stems and other plant fragments; and weed seeds other than the intended seeds. Therefore, we take a sample, perform a physical purity test, and investigate the ratio of the desired seeds. Based on the results, we sort high-quality seeds that can be commercialized from the raw material seeds.

After the physical purity test, we perform a “seed count,” which is a grain count test per gram. We weigh a certain number of grains according to the size of the seeds and then calculate the number of grains per gram. Seed bags delivered to the customer show the quantity of seeds in terms of the number of grains, milliliters, grams, etc. The seed count test results are used for this quantity display.

Testing in compliance with international standards

In our quality control process, Sakata Seed Corporation uses the international standards defined by ISTA*1 (International Seed Testing Association). In particular, our germination test laboratory has been certified as an ISTA accredited laboratory. We are the first private seed company in Japan to obtain this certification. This accredited laboratory can issue internationally-accepted seed quality testing certificates. In order to maintain international accreditation, it is necessary to satisfy various strictly defined requirements.

Germination test

-

*

1 ISTA : International Seed Testing Association. An institution that creates international standards for methods such as sampling, physical purity testing, and germination testing, and other tests required for seed transactions.

Germination test

Germination test using the filter paper method

Germination test using the filter paper method 2

Germination rate displayed on the seed bag. The germination test is conducted to guarantee the germination rate. Germination tests include tests on filter paper and tests in soil. For some tests, the seeds are sown and then left to grow in conditions close to those of the customer. Sakata Seed Corporation strives to supply high-quality seeds while defining and accurately conducting a multitude of tests necessary for ensuring that seeds can be used with peace of mind. For example, our tests determine germinability of seed lots and whether or not they germinate uniformly.

Sakata Seed Corporation is working to move even closer to “quality evaluation from a customer perspective” by introducing the concept of a healthy seedling rate in addition to the germination rate.

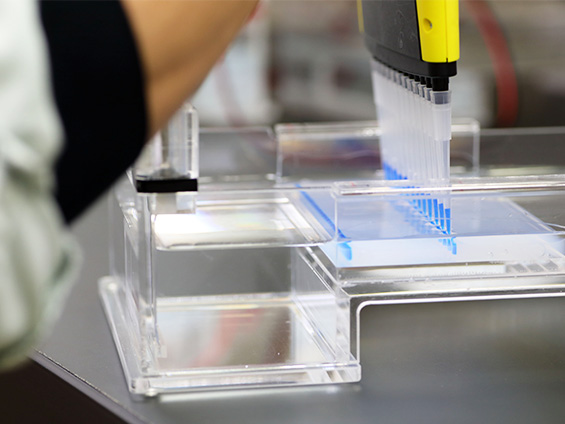

Pathology test

Seeds contaminated with pathogens not only reduce the germination rate of those seeds themselves, but also become a source of transmission to growing areas and may promote the outbreak of diseases. Therefore, we test for contamination of seeds by known pathogens carried by seeds. Moreover, there are sometimes more than one type of seed-borne pathogen in a single seed. In many cases, Sakata Seed Corporation performs multiple tests in order to provide seeds that have been confirmed as safe.

We conduct tests for various pathogens such as filamentous fungi and bacteria to determine the seed health

Genetic purity test using DNA

Cultivation test on research facilities

In addition to the tests introduced so far, we also use DNA tests in our laboratory and cultivation tests on research facilities to conduct genetic purity tests for confirming that the seed lot is truly the desired product, and test to ensure that the seeds are not contaminated with GMO (genetically modified organisms).

In this way, in addition to international standard methods such as ISTA, Sakata Seed Corporation uses its own testing technology to conduct various tests for confirming the quality of seeds. Based on the results of these quality tests, we conduct quality evaluations in accordance with the Sakata Seed Corporation Comprehensive Quality Standards.

Seed processing

To make it easier for customers to use our products with peace of mind, seeds also undergo treatment to improve the uniformity of germination and pellet processing to make it easier to sow fine seeds. The seeds packed in our seed bags are the finished goods that have undergone repeated verification and testing from the stage of raw material seeds, and that have been treated and processed.

Seed disinfection is a treatment that is often performed in conjunction with seed processing. The photograph shows a pesticide smear